COVEC®

Known for their exceptional durability, Covec® fabrics are in a class of their own.

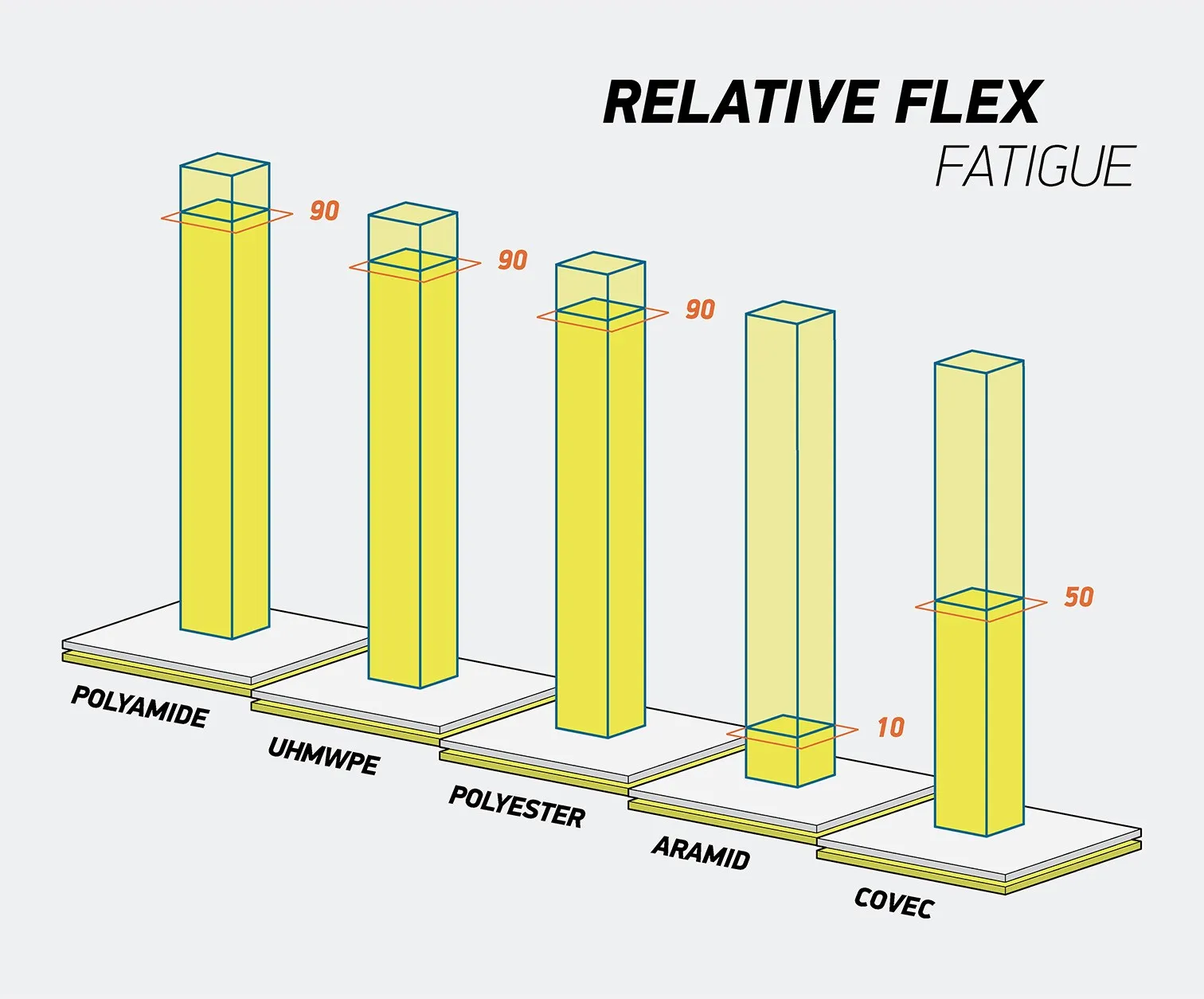

Covec® textiles are characterised by low flex fatigue, which ensures prolonged performance compared to traditional materials like those in the graphs below.

Compared to Aramids – such as Kevlar – Covec® yarns provide even higher abrasion resistance and lower friction heat transfer.

LOW FLEX FATIGUE

Flex fatigue is the loss of strength after repeated bending or folding. This happens both during use and while cleaning the jeans.

Where Polyamides like Nylon deteriorate rapidly in the washing machine, Covec® easily withstands the removal of sand, rain, dirt, sweat, and bugs by machine.

Covec® yarns are exceptionally durable and last nearly twice as long as most traditional fabrics, as shown here on the right.

PROLONGED PERFORMANCE

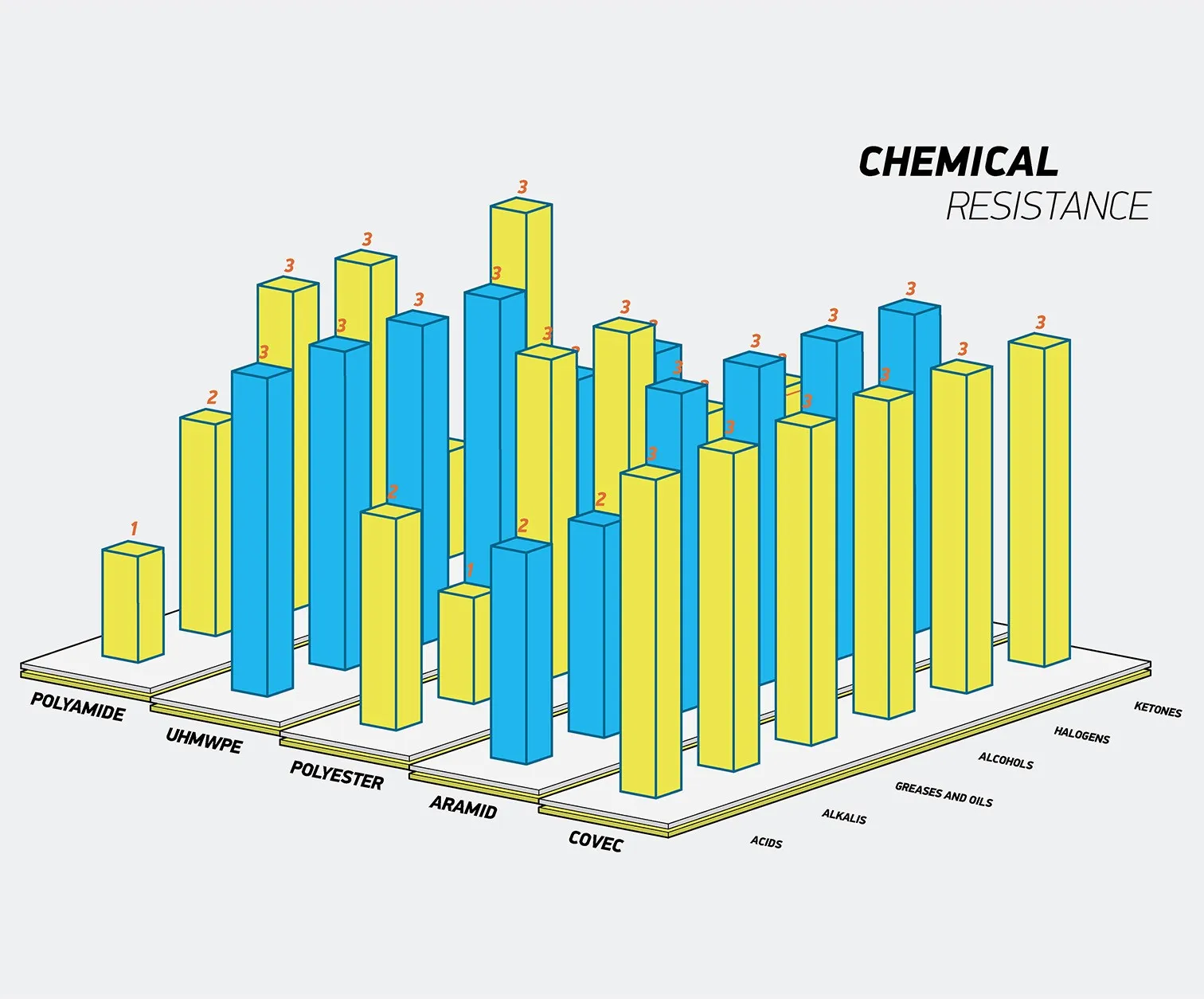

There are many chemicals that can come into contact with your gear. Many of these chemicals can have a degenerating or even devastating effect on polymers.

When a material retains moisture, it will weaken over time, with chemicals often functioning as catalyst. Aramids for example can retain up to 7% of moisture, while Covec® only retains 0.01%.

This graph shows the relative scores on chemical resistance per material and chemical type, where 1 is poor, 2 is fair, and 3 is good.

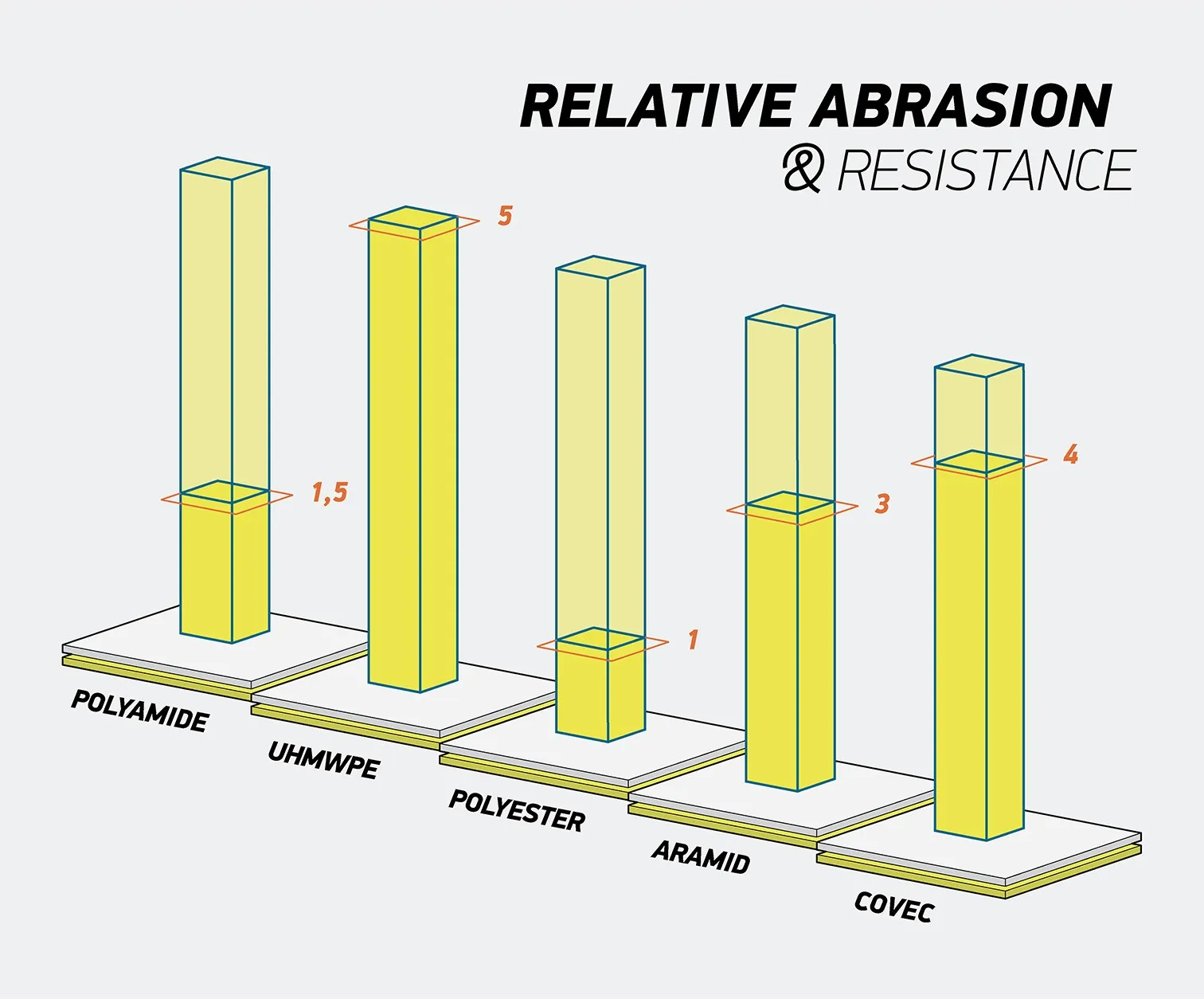

ABRASION RESISTANCE

Covec® fabrics are CE tested and provide the highest possible abrasion resistance: up to almost 8 seconds according to EN 13595-1. This results in unrivalled CE level 2 motorcycle jeans.

The polymer in Covec® yarn was tested by NASA as a replacement for Aramids in 2004. It was used for the Mars Rover space missions, providing the spacecraft with protection against impact and abrasion.

If you score the different fibres used in motorcycle clothing against toughness, specific tenacity, and elongation at break, you get the following results:

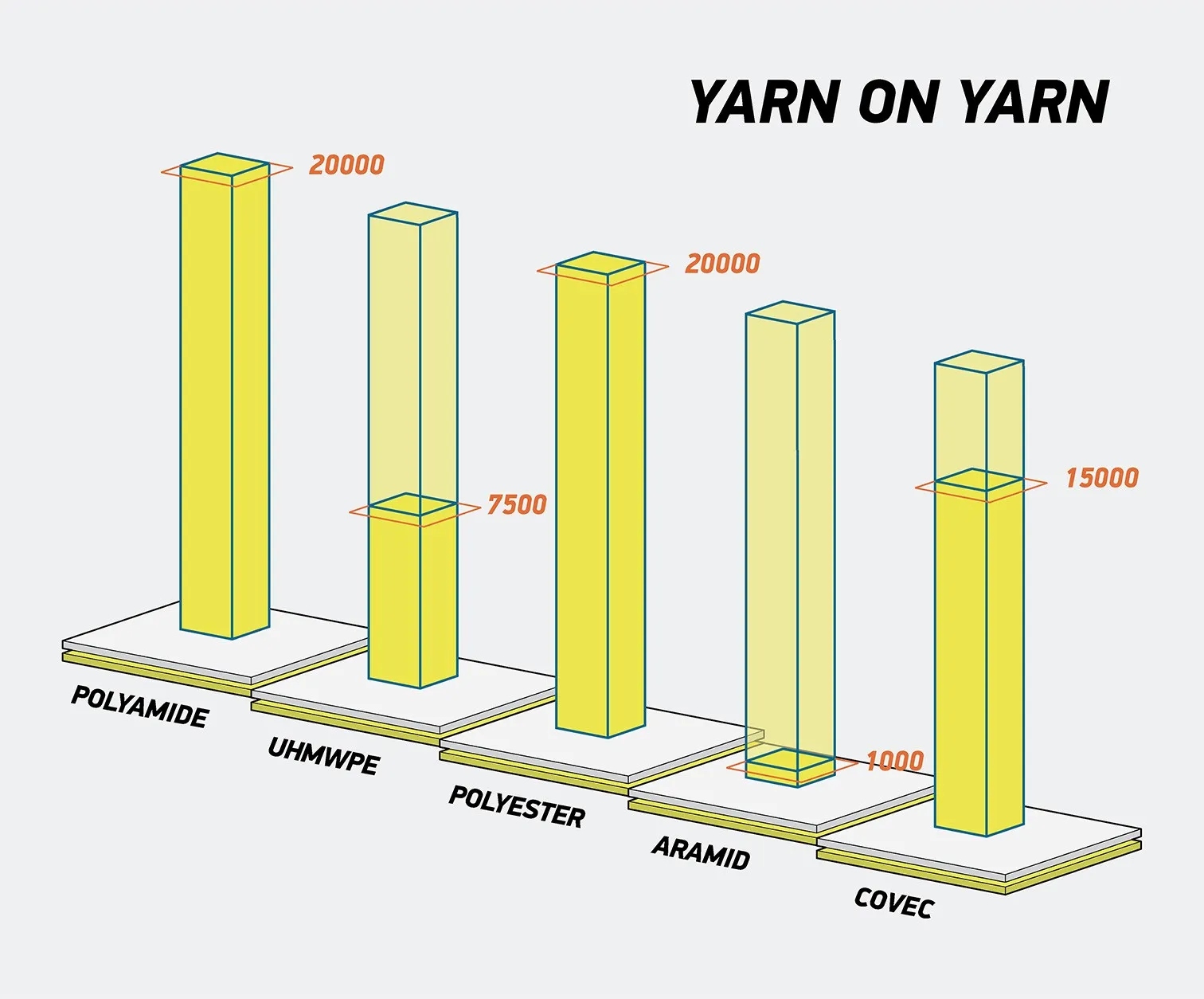

YARN ON YARN

Less well-known but just as important is yarn-on-yarn abrasion: the effect of the yarns in a fabric rubbing against each other.

The scores in this graph indicate the cycles to break on a standard (dry) yarn-to-yarn abrasion test setup.

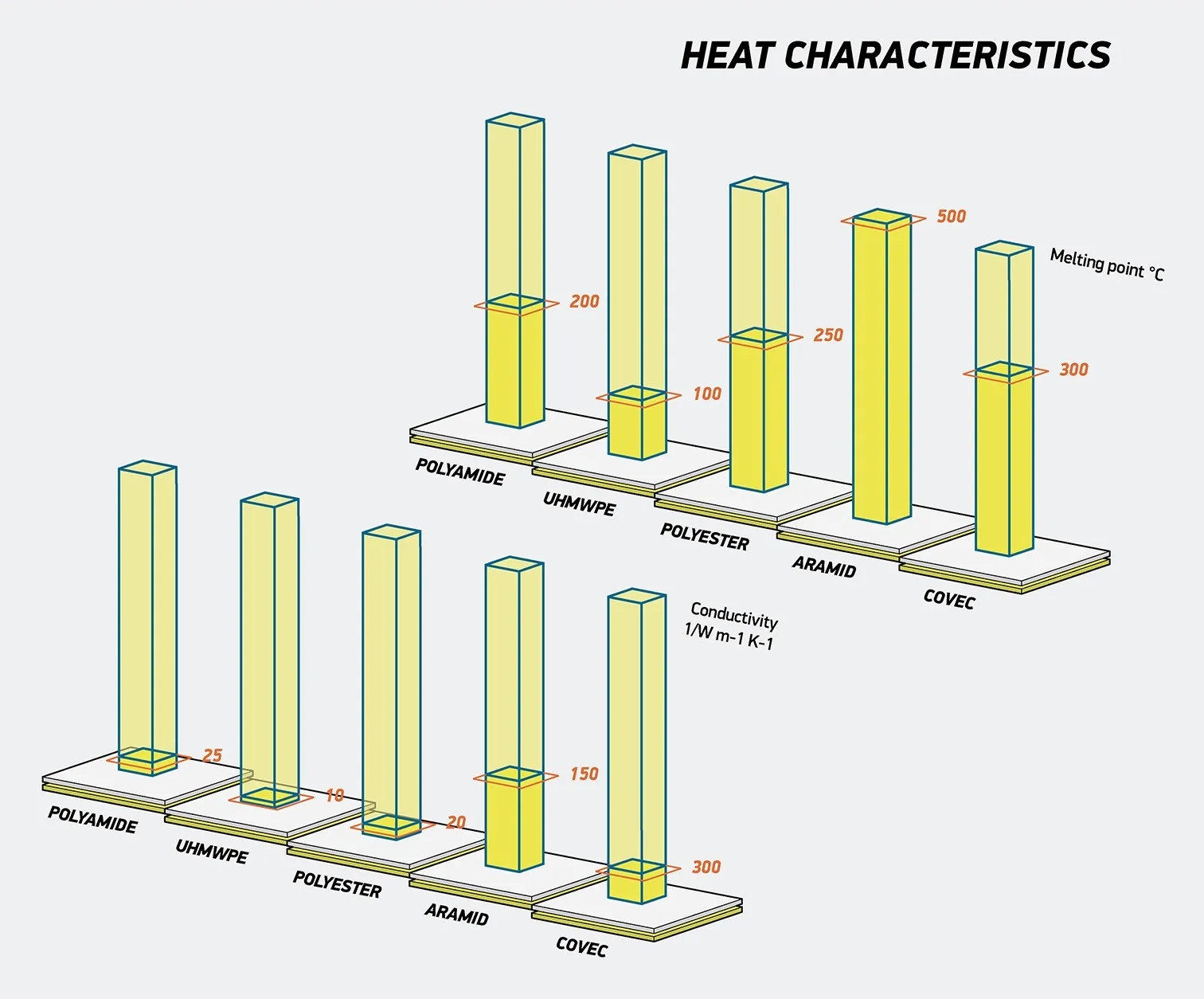

FRICTION HEAT TRANSFER

Covec® provides low thermal conductivity and a high melting point, preventing additional burns in a crash scenario. For the materials in the graphs, either one or both of those criteria work the other way around.

As high thermal conductivity (Aramid) and/or a low melting point (UHMWPE) are less suitable in situations where heat is produced by friction against abrasive surfaces, Covec® is the superior choice when it comes to heat transfer.

COVEC®

Now you know the benefits of Covec®. Want to find out more about other fabrics we use? Return to the Materials page and scroll down to continue your adventure.