MATERIALS

If you happen to get caught in an unintentional game of ride-n-slide, abrasion resistance is your main priority after impact protection.

The materials used in our riding gear are selected on their high levels of performance against abrasion, tearing, and heat.

Below you’ll find a selection of our most special constructions and materials, such as fully woven (singe layer) jeans, SuperFabric® reinforcements, and the versatility of aramid fibres.

HEAT SHIELD

SINCE 1999

Heat-resistant material with a very high melting point on the outer shell at the bottom of the legs. Prevents a meltdown whenever your exhaust and pants accidentally meet each other.

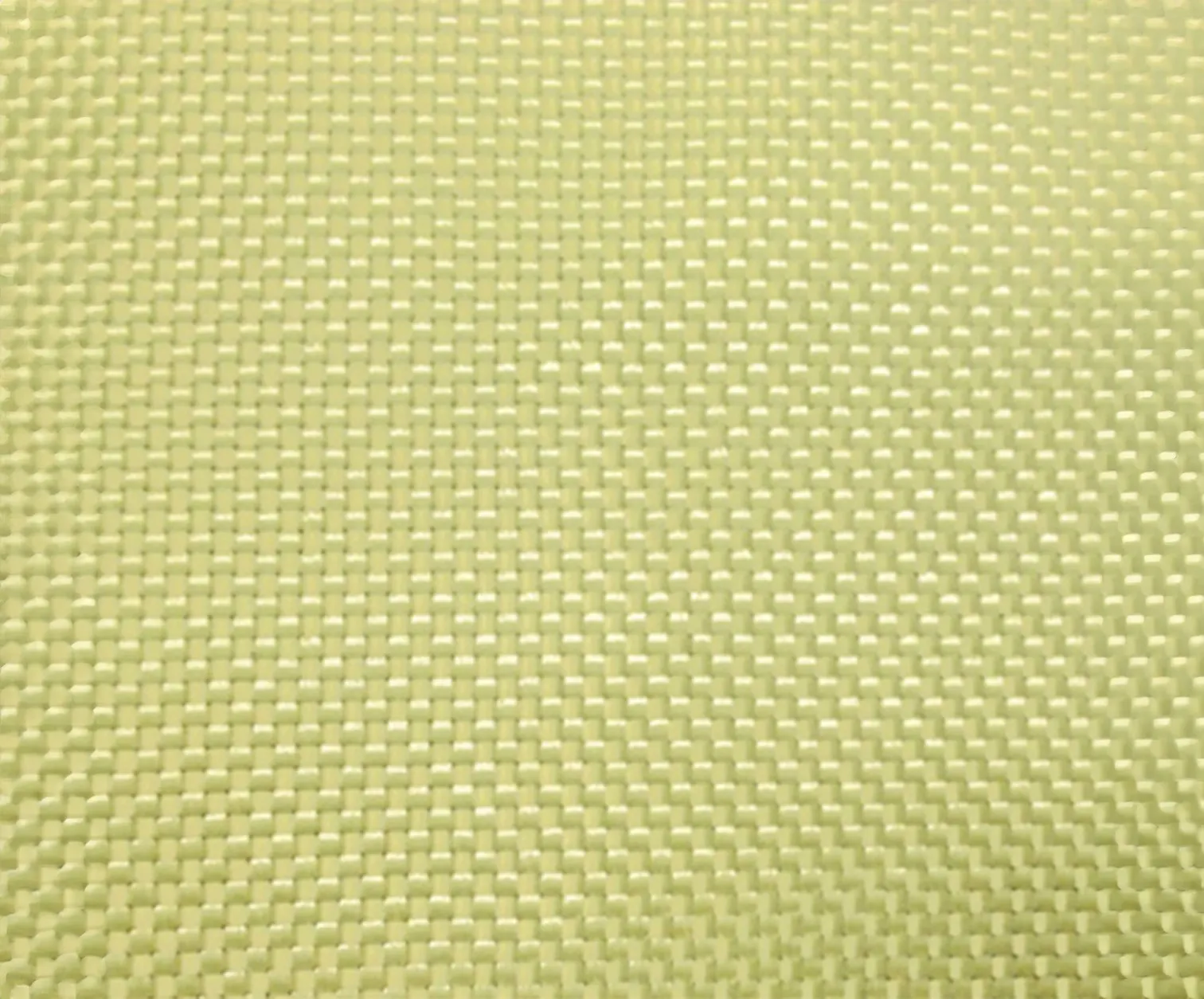

SUPERFABRIC®

SINCE 2011

SuperFabric® is a highly abrasion-resistant material. The fabric is overlaid with countless little guard plates on top that are arranged in a way that allows flexibility without sacrificing performance.

They are coated in a resin that is also used in the production of helmets and can withstand aggressive abrasion – and are also highly slash- and rip resistant.

So all in all, an effective additional layer of protection in key areas. You’ll find it in our gloves, jackets, pants, and even our MotoGP suits, where they cover critical seams.

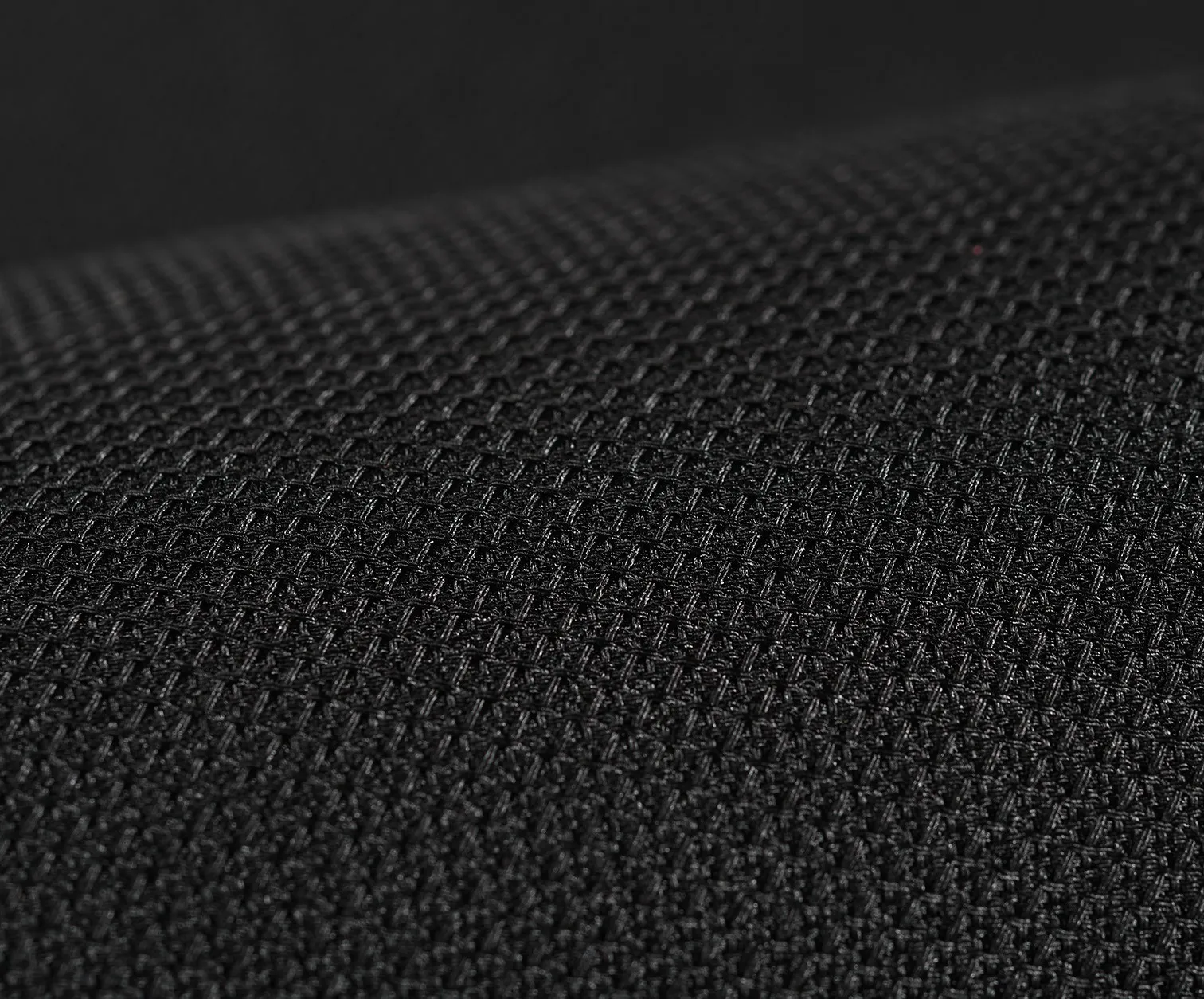

CORDURA FULLY WOVEN

SINCE 2013

Cordura fibres are incorporated during the manufacturing process, due to which it is fully woven into the outer shell of the garment, creating a single-layer jeans.

Provides a high level of resistance against abrasion, cuts, and tears, and improved breathability compared to reinforced pants.

ARAMID FULLY WOVEN

SINCE 2013

Aramid fibres are incorporated during the manufacturing process, due to which it is fully woven into the outer shell of the garment, creating a single-layer jeans.

Provides a high level of resistance against abrasion, cuts and tears, and improved breathability compared to reinforced pants.

ARAMID REINFORCED

SINCE 2013

Impact areas are reinforced on the inside with a layer of Aramid fabric against the outer shell. Provides extra resistance against abrasion, rips and tears where it is most important.

ARAMID DYNAMIC STRETCH

SINCE 2014

The strength of Kevlar with the stretching capabilities of Spandex. Dynamic aramid stretch is a strong and durable double-weave fabric with aramid yarns.

This material has 4-way stretch that provides our racing suits with an optimal fit and high level of comfort at the highest level of motorcycle racing.

ARAMID REINFORCEMENTS

SINCE 2018

An invisible line of defence on the inside of racing gloves.

The liner is made of aramid fibres to raise resistance against abrasion, rips, tears, and heat.

KANGAROO LEATHER PALM

SINCE 2019

The palms of racing gloves are reinforced with a double layer of premium-quality kangaroo leather to provide a very high level of abrasion resistance in the event of a crash.

Due to its high abrasion resistance, kangaroo leather enables us to use a thinner piece which in turn provides better feeling at the handlebars.

RIPSTOP

SINCE 2019

Strong fabric with a fine squared pattern texture with reinforced yarns that makes the material stronger and very resistant to tearing.

Different variants of ripstop are used in our riding gear, depending on the style and intended use of the garment.

CALORITE

SINCE 2023

An abrasion-resistant fabric that is sometimes used as reinforcement in critical areas such as the shoulders, elbows, or knees.

COVEC® FULLY WOVEN

SINCE 2025

Known for their exceptional durability, Covec® fabrics are in a class of their own.

Covec® textiles are characterised by low flex fatigue, which ensures prolonged performance compared to traditional materials such as Polyester and Nylon. Compared to Aramids – such as Kevlar – Covec® yarns provide even higher abrasion resistance and lower friction heat transfer.

MATERIALS

Now you know the benefits of some of the special materials we use to keep you safe. Want to find out more about other forms of protection? Return to the Safety page and scroll down to continue your adventure.