MISSIE BRIEFING

Om de veiligheid van onze producten en dus van motorrijders te blijven verbeteren, worden onze ontwerpers voortdurend uitgedaagd. In dit geval kregen ze de opdracht om de beruchte zwakste schakel tijdens een crash te vinden en te herzien.

Na analyse van honderden pakken en handschoenen die betrokken waren bij crashes met hoge snelheid, crashes met lage snelheid, high siders en low siders, bleek de zwakste schakel allesbehalve verrassend te zijn: de naden.

Wat ons wel verraste: naden zijn te vinden in alle belangrijke impactzones zoals ellebogen, knieën en schouders. Heeft de industrie de boel bij elkaar gehouden met een touwtje? Jakkes! Dit kan wel wat macnaficatie gebruiken.

DESIGN PROCES

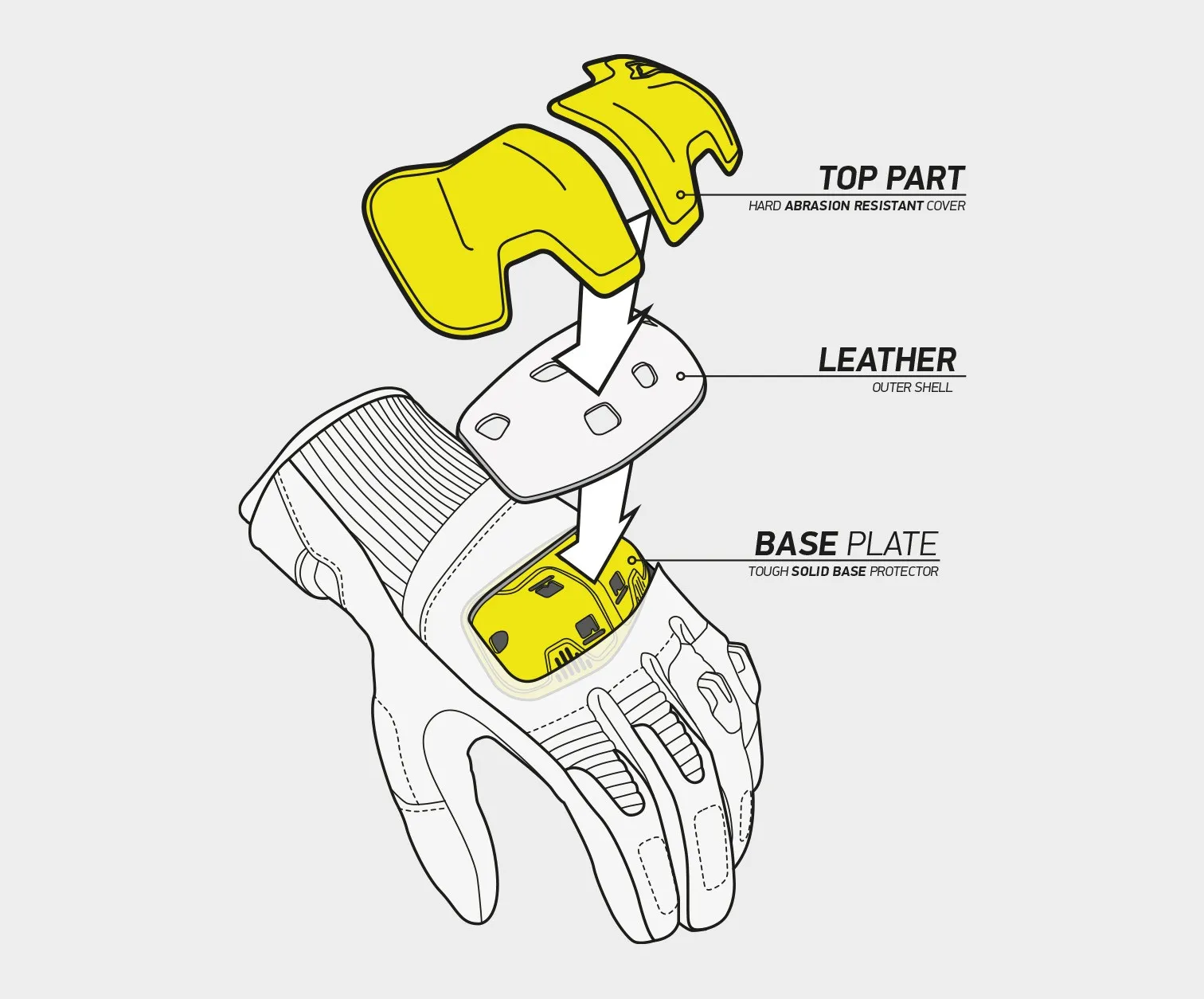

Maak een grote opening in het leer dat je moet beschermen. Plaats een protector en verbind de delen met elkaar door middel van naden – wat nu het zwakste deel van de constructie is. Dat klinkt niet als een geweldig idee.

En toch is dit de traditionele manier om een protector op leer aan te brengen. Het doel was dus duidelijk: weg met de naden in de impactzones. Leer hecht zich echter niet op magische wijze aan andere delen. Dit vereiste enige innovatie.

We kwamen er al snel achter dat het niet gebruiken van naden bij de schouders bijna onmogelijk is vanwege de constructies. Dit resulteerde in het concept van een stevige basisprotector die wordt bevestigd door naden en een harde slijtvaste cover die wordt vastgezet met een lijmoplossing.

Andere impactgebieden – zoals ellebogen, knieën, knokkels, vingers en palm – maakten het wel mogelijk om de base protector en slijtvaste hoes met elkaar te verbinden zonder het gebruik van naden. De sleutel tot succes was het minimaliseren van de grootte en de hoeveelheid uitsparingen in het leer, waardoor de algehele sterkte sterk toenam en naden overbodig werden.

RESULTAAT

Je hebt vast wel eens gehoord van de uitdrukking “een ketting is zo sterk als zijn zwakste schakel”. Hetzelfde kan gezegd worden van de naden in een pak, want die zijn het zwakste deel van de constructie. Daarom hebben we een manier gezocht en gevonden om de veiligheid te vergroten door op kritieke plaatsen geen naden te gebruiken. Het resultaat: Armax™

VEILIGER

Geen naden om overheen te glijden verhoogt de slijtvastheid en dus de veiligheid aanzienlijk.

AERODYNAMISCHER

De afwezigheid van naden maakt het oppervlak gladder en verhoogt zo de aerodynamica.

MOOIER

Alle afzonderlijke delen kunnen verschillend gekleurd worden, waardoor ze perfect bij de rest van het pak passen.

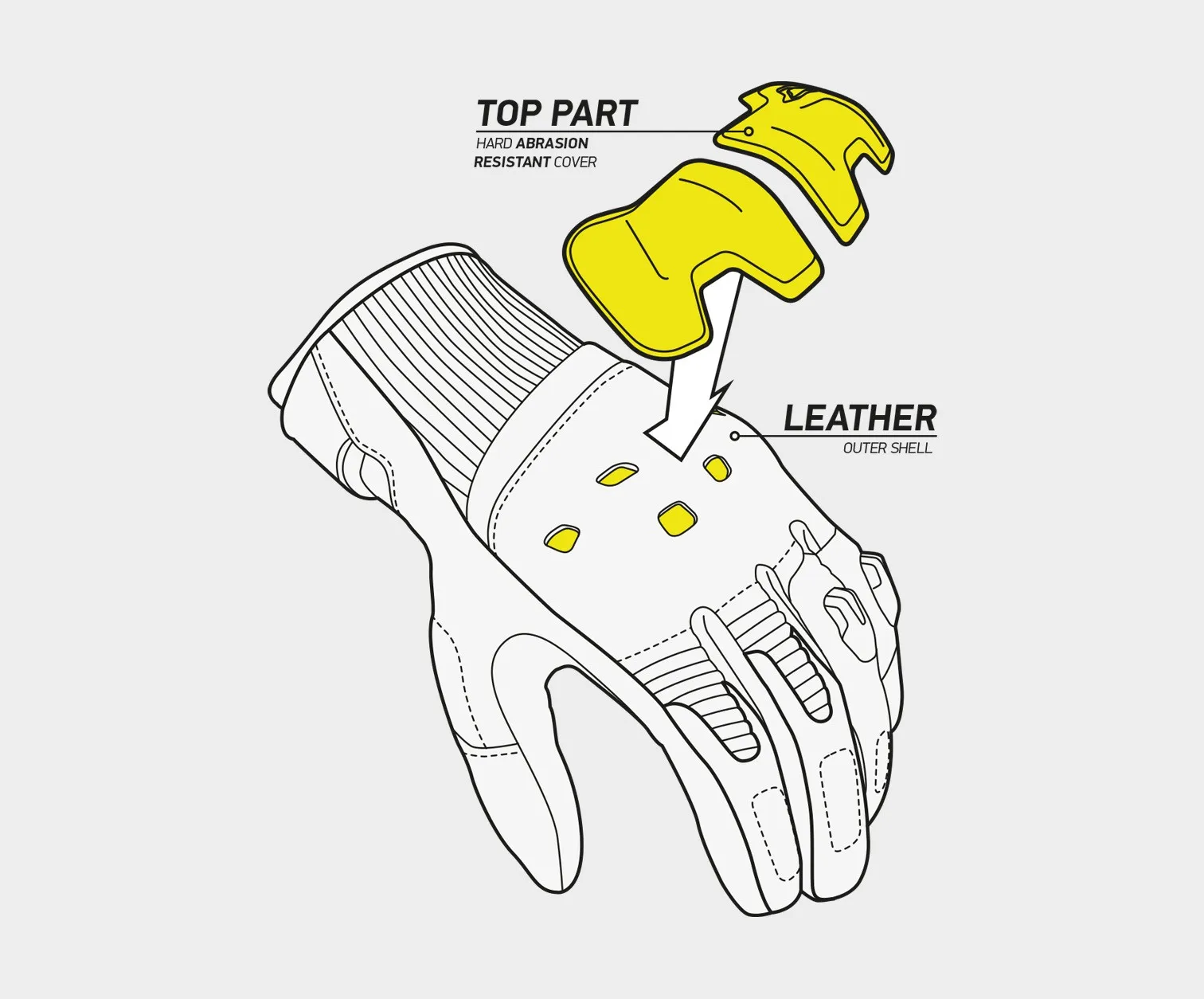

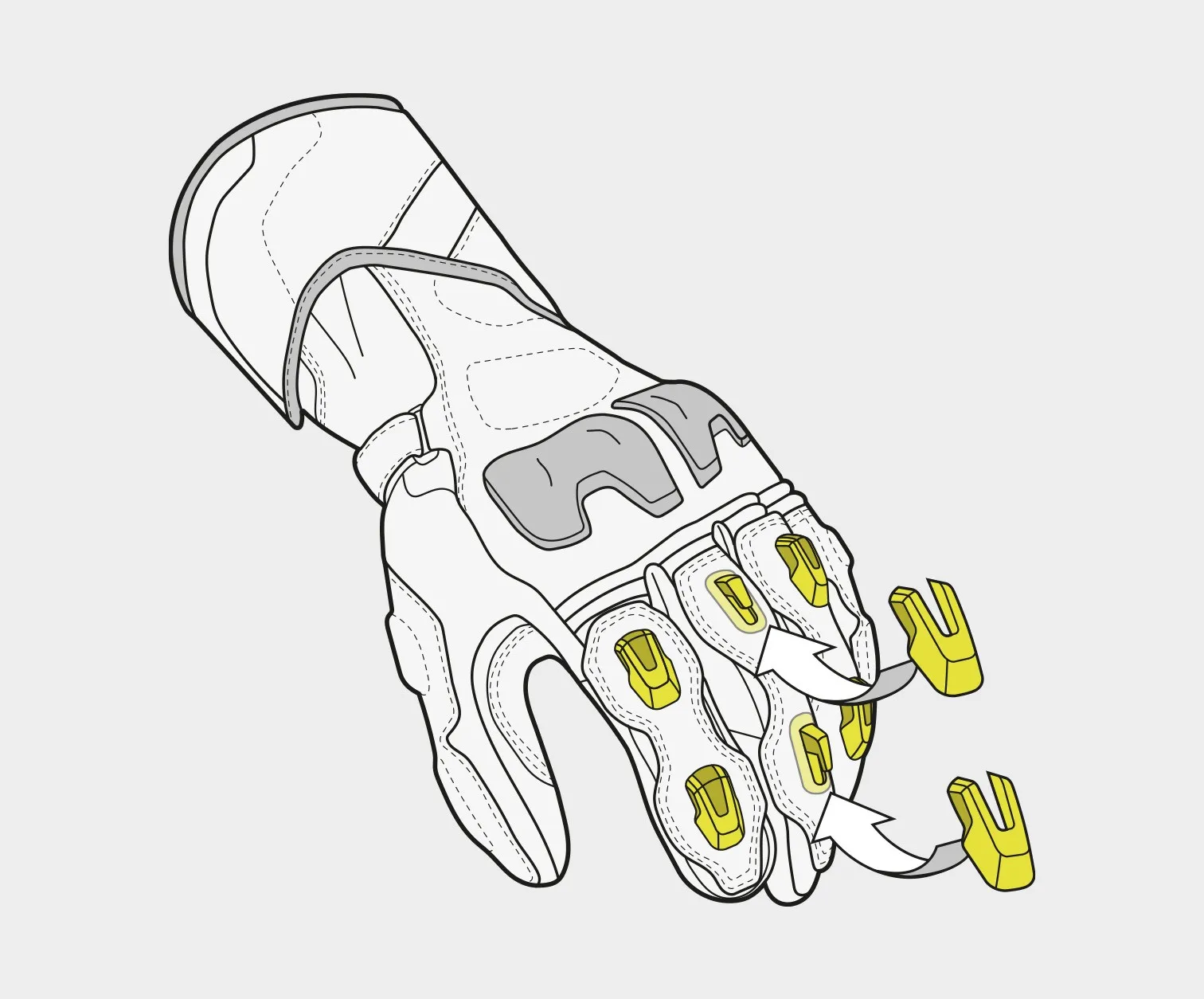

KNOKKELS

SINDS 2021

Dit gepatenteerde ontwerp is ontwikkeld met veiligheid als belangrijkste focus. Een harde slijtvaste cover is gemonteerd op een stevige basisplaat bij de knokkels. Dit beschermt je knokkels tegen inslag en kan als slider fungeren. Door het naadloze ontwerp is het knokkeldeel minder onderhevig aan slijtage.

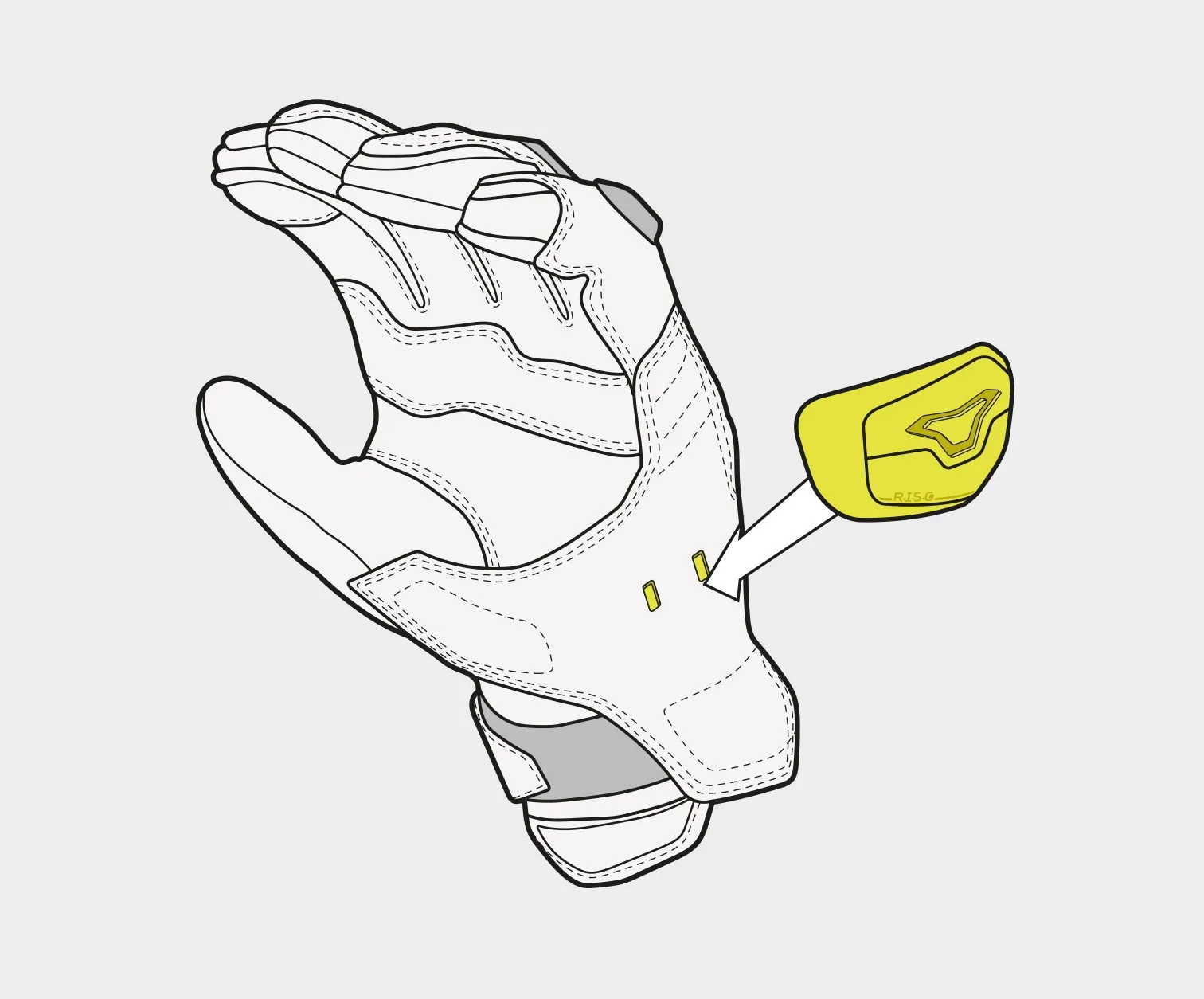

PALM

SINDS 2021

De ergonomisch gevormde palm protector werkt als een glijpad, maar verspreidt ook de kracht van de inslga, waardoor letsel aan het beruchte scafoïd-bot tot een minimum wordt beperkt. Onze Armax™ palm protector is aan de handschoen bevestigd met slechts twee kleine gaatjes en zonder naden. Zo blijft het leer zo veel mogelijk intact en blijft de handschoen zo sterk mogelijk.

VINGERS

SINDS 2021

Externe harde protectie-elementen op de vingers. Ze beschermen tegen inslag en kunnen ook dienen als kleine sliders. Bevestigd op de vingers zonder grote gaten te maken of naden te gebruiken, waardoor het leer zo stevig als een rots blijft.

MANCHET

Sinds 2024

De buitenkant van het lichaam komt bij een val meestal in contact met het wegdek.

Naast de knokkels, vingers en palm is Armax™-protectie nu ook beschikbaar voor de manchet van de handschoen om de kwetsbare pols te beschermen.

SCHOUDER

SINDS 2021

Om de schouder te beschermen, wordt er een stevige basisplaat van nylon versterkt met glasvezel vastgezet in de schouder. Bovenop de basisplaat wordt vervolgens een harde slijtvaste cover gemonteerd, die alles stevig op zijn plaats houdt.

Deze schouder protectoren bieden je protectie en slijtvastheid en zijn ijzersterk. Ze voegen veiligheid en duurzaamheid toe door de naden op kritieke plaatsen af te dekken. Het strakke Armax™ ontwerp heeft veiligheid er nog nooit zo goed uit laten zien.

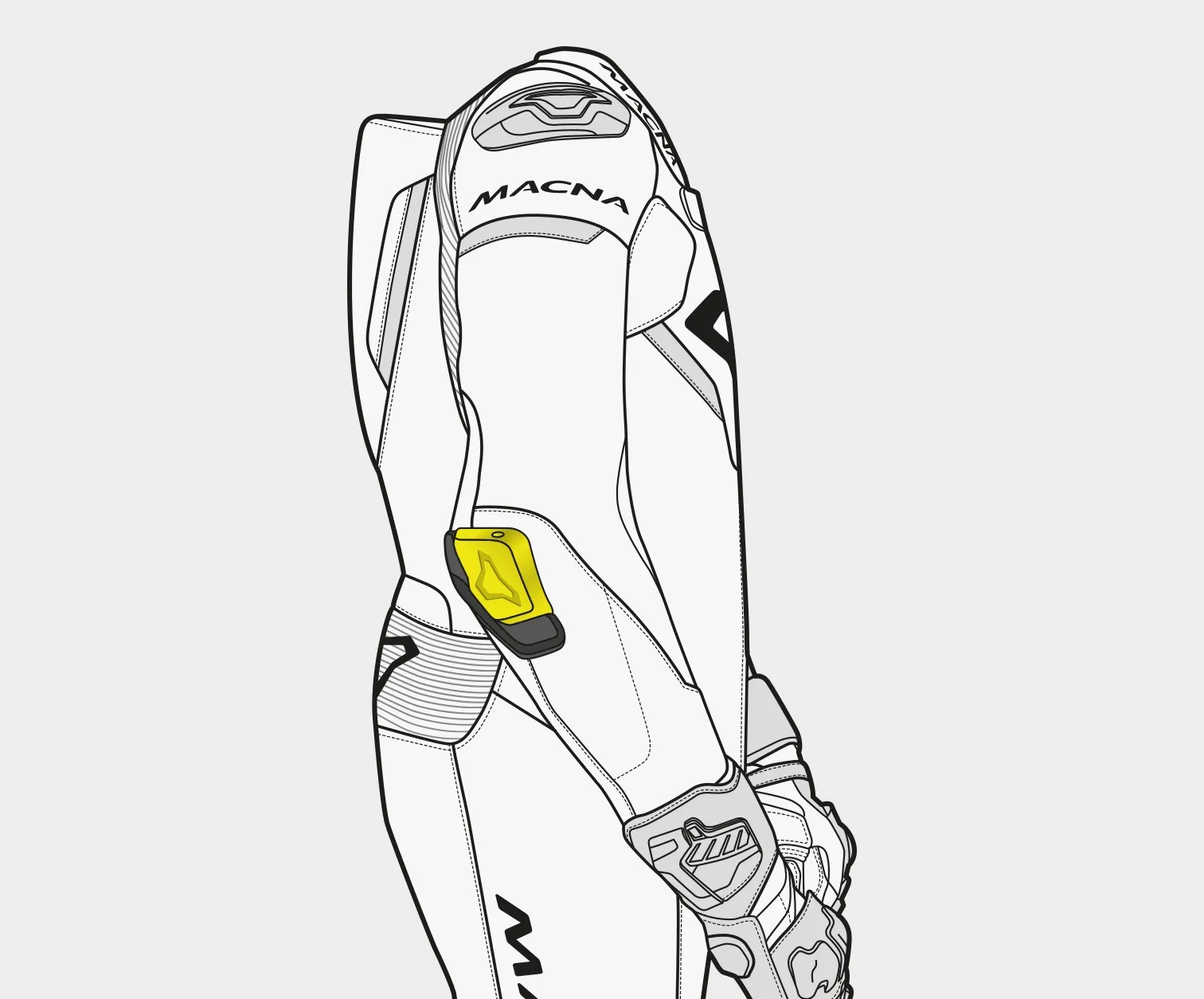

ELLEBOOG

SINDS 2024

Nu de elleboog. Impactprotectie, slijtvastheid en een strak design.

Armax™ op de elleboog is niet alleen protectie, maar ook een slider.

De bout waarmee de slider vastzit, zit anders dan normaal. Dit is gedaan omdat de traditionele positie ervoor zorgt dat de bout tegen de ondergrond schuurt als je sliders dunner worden.

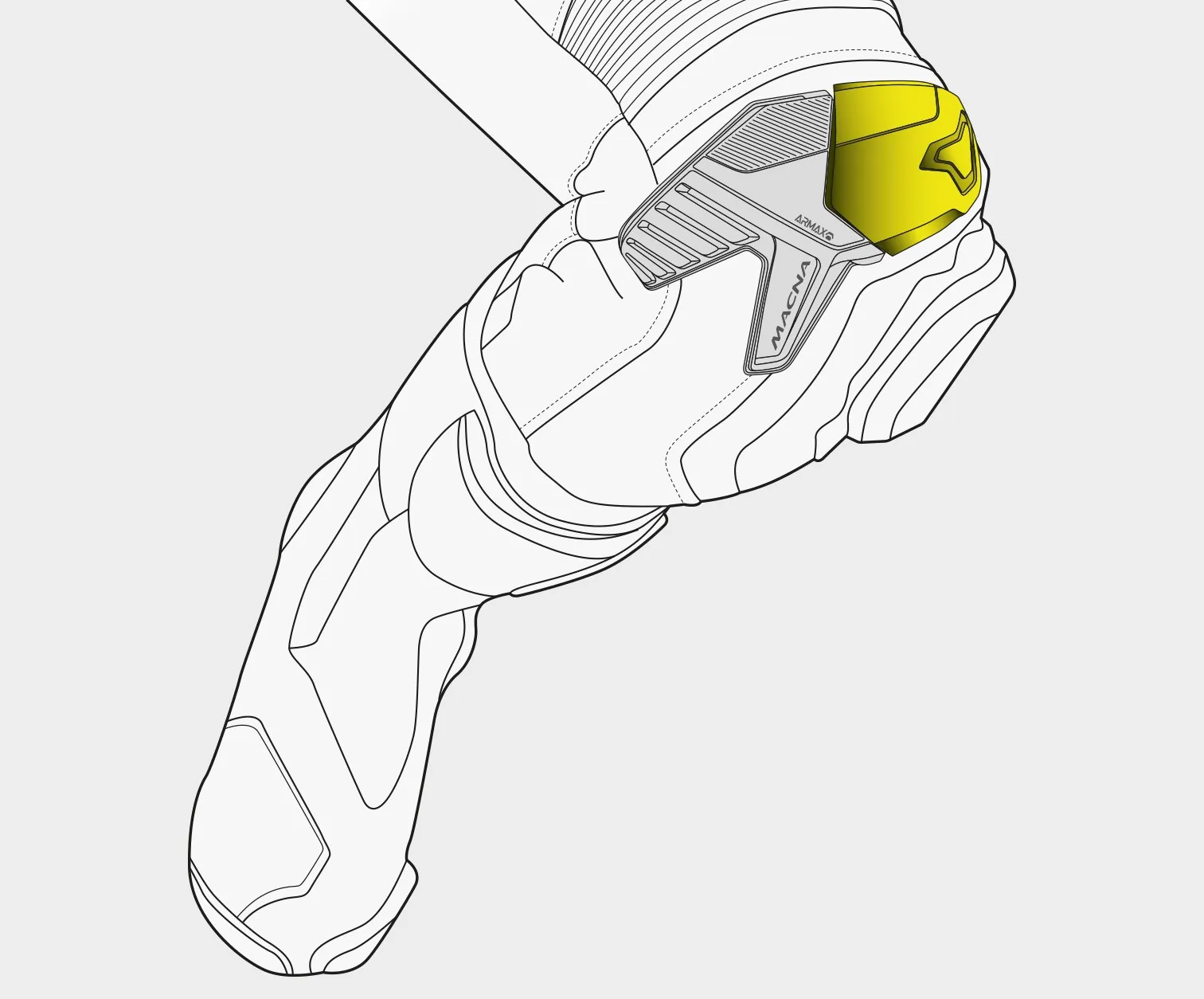

KNIE

Sinds 2024

Om af te sluiten nemen we een knietje; een Armax™-knie om precies te zijn.

Naast de voordelen die je nu waarschijnlijk in je slaap kunt opsommen – inderdaad, schokabsorptie en slijtvastheid – biedt Armax™ op de knieën ook een hoge mate van grip.

Het tweede deel van de knieconstructie is gemaakt van rubberachtig TPR dat zorgt voor een beter gevoel op de motor zonder de lak te beschadigen.

ARMAX™

SINDS 2021

Nu ken je de voordelen van Armax™ protectie. Wil je meer weten over andere vormen van protectie? Ga terug naar de pagina Veiligheid en scroll naar beneden om je avontuur voort te zetten.